Description

For small and medium sized LNG devices (<2.3 million m3/day), Shaangu developed EBZ series centrifugal compressors with single cylinder (one compressor unit) and single refrigerant circulating. The models are shown in the table below.

| No. | Model | Processing Capacity |

| 1 | EBZ35 | 0.15~0.3 million m3/day |

| 2 | EBZ45 | 0.3~0.5 million m3/day |

| 3 | EBZ56 | 0.5~0.8 million m3/day |

| 4 | EBZ63 | 0.8~1.2 million m3/day |

| 5 | EBZ71 | 1.2~1.8 million m3/day |

| 6 | EBZ80 | 1.8~2.3 million m3/day |

For large LNG plants, two or three cylinders compressor are adopted according to different refrigeration processes.

The EBZ series barrel type centrifugal compressor is adopted by Shaangu LNG mixed refrigerant machine train. The structure has inner cylinder and outer cylinder to ensure extremely low leakage and noise. Meanwhile, another advantage of the compressor is easy maintenance, since the inner cylinder could be pulled out directly without related pipes removed. The code definition is as follows:

The flow range of EBZ series centrifugal compressor is 10~3000m3/min, exhaust pressure is up to 25MPa. Serialization design, efficient three-dimensional impellers and proper matched model stages make sure pressure ratio requirements and high-efficient operation.

The compressor is equipped with special vortex slot and axial slot structure to eliminate the vortex of the overflow gas and the turbulence caused by the vortex on the rotor, increase the rotor damping, reduce the rotor vibration and improve the stability of the rotor.

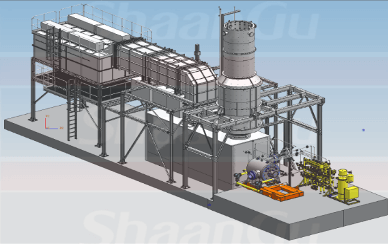

The innovative integral skid-mounted structure meets the small workshop space, small inspection and maintenance space, low civil construction cost and less on-site installation, which greatly facilitates customers.

| No. | Item | Integral Skid-mounted Base Frame | Traditional Base Frame |

| 1 | Layout |

Compressor, gearbox, lube oil console, dry gas sealing system, oil pipe system and lube oil cooling system are integrated on the combined baseframe with single-floor layout, no second-floor platform is required. |

For traditional combined baseframe or separated baseframe, the equipment is shipped to the site separately, the oil pipeline beside machine and dry gas seal control panel are arranged on the concrete foundation beside the machine. The lube oil console is arranged on the first-floor platform, while the compressor is arranged on the second-floor platform. |

| 2 | Floor area | Floor area could be reduced by over 40%, compared with the traditional compressor unit. | Large floor area. |

| 3 | Height of workshop | No need for the second-floor platform. Height of the workshop is 5~7m lower than that of the traditional workshop with two platforms and downward inlet & outlet of compressor, and 2~3m lower than that of the workshop with one platform and uoward inlet & outlet of compressor. | Compressor is arranged on the second-floor platform, which increases the height of workshop and the investment cost. |

| 4 | Quantity of civil works | Only pile foundation layout is needed. Minimum foundation civil work is needed. | Frame-type concrete structure or block-type concrete above the ground level is required. |

| 5 | On-site installation cost and convenience | Most are prefabricated in factory, only mechanical bolted connection is required on site. | Pipeline prefabrication and instrument wire arrangement need to be done on site. |

By December 2019, Shaangu has achieved nearly 30 sets of mixed refrigerant single-cycle refrigeration compressor trains in operation, which include the traditional layout compressor units with downward inlet & outlet and two operation platforms, as well as the integrated skid-mounted units.

In the LNG refrigerating process, there is also propane pre-cooling + mixed refrigerant refrigeration process, especially in some large LNG plants, which are more common.

Shaangu provides propane refrigeration compressor trains for natural gas liquefaction plants.

In 2011, Shaangu won an overseas contract to provide 33 sets of skid-mounted propane refrigeration compressor units for a natural gas liquefaction project, which is the largest refrigerant unit order Shaangu has received. The train has completed the performance test conforming to ASME PTC10 before delivery. At present, the units have passed the field performance test and has been put into operation successfully. All parameters of the units meet the requirements.

Through the product performance test, the complete unit performance reaches the international advanced level. It adopts the skid-mounted scheme, which brings convenience for customers to install, and has realized the intelligent function application, such as one-button startup and unattended operation.

Reviews

There are no reviews yet.