Serialization design, efficient three-dimensional impellers and the proper matched model stages realize pressure ratio requirements and high-efficient operation.

E series compressors are designed with mature and reliable modeling stages and advanced pneumatic calculation program, reaching international advanced technology level by many fields operation verification.

Rich-gas Compressor for Coking Unit.

EZ series centrifugal compressor could be used as rich-gas compressor in the catalytic cracking unit.

Size of EZ compressors covers from EZ28 to EZ160 with flow range of 20~7000m3/min, which could be served for the heavy oil cracking and delayed coking plants with capacity of 0.2-2 million T/y, and also the combined needle coke units with capacity of 100,000-300,000 T/y.

The rich-gas compressor is characterized by:

High polytropic efficiency, better than that of domestic peers, and the same level with the technology of leading international companies.

Compressors for PX/PTA Plants

Shaangu supplies EG integrated gear type compressors for PTA plants.

EG compressors are jointly developed by overseas R&D team and domestic technical team of Shaangu, adopting mature and reliable model stage and advanced pneumatic calculation program, which has been approved by the market and reached the international advanced technical level, and won the second prize of National Science and Technology Progress Award.

Maximum flow rate: 14000 m3/min

Maximum discharge pressure: 7.2MPa

Maximum speed: >35000r/min

Stage polytropic efficiency >88%

Shaangu provides the compressor unit for 1.5 million T/y PTA plant of Jiangsu Honggang Petrochemical, which adopts the configuration of steam turbine + EG compressor + expander. In June 2014, the unit was putting into operation with excellent performance. In May 2015, the unit was verified by designing institute, users and Shaangu jointly, and reached the international advanced level.

Circulating hydrogen centrifugal compressor for hydrogenation and reforming units.

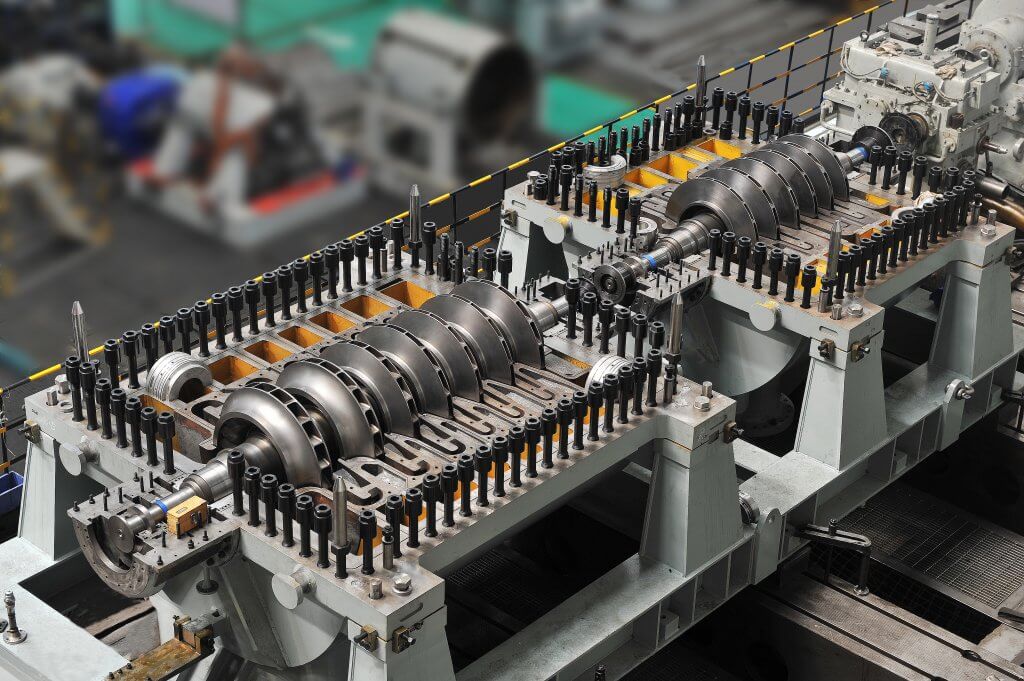

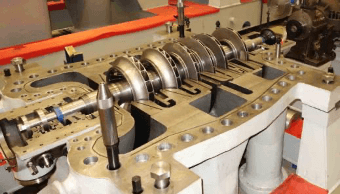

EB barrel type centrifugal compressor is special designed for circulating hydrogen process:

The model covers EB28~EB125.

The flow: 10 ~ 3000m3/min, and exhaust pressure: up to 25MPa.

Serialization design, efficient three-dimensional impellers and proper matched model stages realize pressure ratio requirements and high-efficient operation.

Rotor and inner stator could be pulled out directly for maintenance without removing the pipes.

Intake and exhaust air ducts could be flexibly designed according to actual situations.

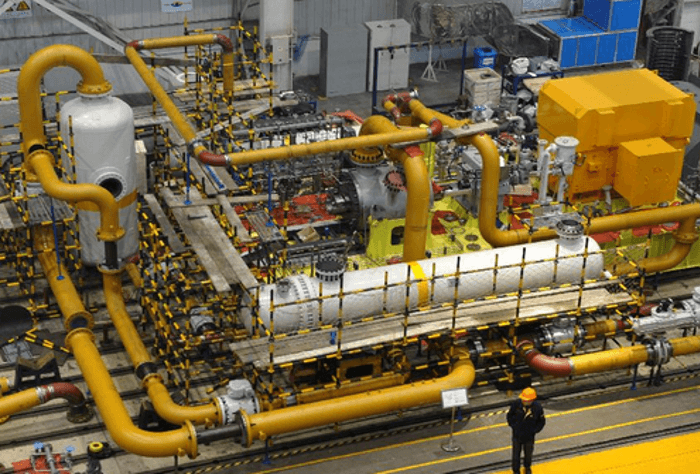

Compressor Unit for Gas Regulator Station of Gas-steam Combined Power Generation Plant

Gas-steam combined power generation plant, as an environment-friendly power generation technology, is widely used in urban peak regulation power plants.

Shaangu provides centrifugal compressor for boosting and centripetal turbine energy recovery unit for the gas regulator station of gas-steam combined power generation plant.

The boosting centrifugal compressor adopts EB barrel type centrifugal compressor, or E series horizontal split centrifugal compressor. The compact skid-mounted baseframe saves the floor area of customers. In addition, the compressor unit is designed with intelligent one-key startup and unattended control functions, and its efficiency and operation range have reached the international advanced level.Propane/mixed Refrigerants Compressor Train

Propylene is an important chemical raw material. In recent years, propane dehydrogenation compressor has developed rapidly. Relying on special axial and centrifugal compressor technologies, Shaangu maintains the domestic leading level in this field. Shaangu provides the complete set of compressors for the dehydrogenation process system.

The applicable models provided by Shaangu: AV/ED/ES series compressors.

AV axial compressor is applied for regenerated gas compression in propane dehydrogenation process.

ED centrifugal compressor is applied for product gas boosting, with characteristics of the following:

-Flow rate covers 90~14000m3/min. The serialization design, efficient three-dimensional impellers and proper matched model stages realize pressure ratio requirements and high-efficient operation.

Double-suction structure meets large flow operation condition.

Water spraying device equipped in the compressor realizes online medium gas cooling to avoid the gas coking caused by high temperature, so as to ensure long-term stable operation of the unit.

ES series centrifugal compressor is applied for boosting of ethylene or propylene refrigerants, which designed with one or more stages of gas compensation section.

Shaangu is the only supplier in China to provide complete set of compressors for ethylene or propylene refrigerant process system. Efficiency of the compressors has reached the international advanced level.