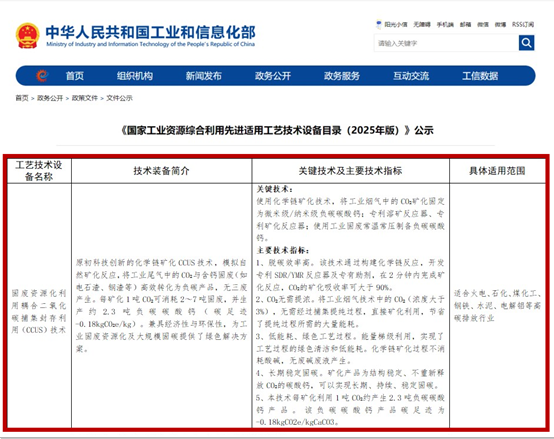

Recently, the Ministry of Industry and Information Technology of China officially released the National Catalogue of Advanced and Applicable Technologies and Equipment for Comprehensive Industrial Resource Utilization (2025 Edition). Among the selections, ShaanGu’s independently developed “Solid Waste Resource Utilization Technology Coupled with Carbon Capture, Utilization, and Storage (CCUS)” was included under the category of “Comprehensive Industrial Solid Waste Utilization”.

Leveraging its innovative technologies and expertise in energy conversion and environmental protection, ShaanGu develops tailored energy-saving and high-efficiency solutions for its customers by focusing on local energy planning and energy efficiency optimization. The company conducts systematic analysis and design around process characteristics, CO₂ capture rates, zero-leakage requirements, and gas-liquid separation. Furthermore, ShaanGu employs advanced aerodynamic simulation technologies in compressor design. By optimization of model stages, sealing systems, flow path components, and intelligent control systems of compressors, ShaanGu’s compressor units achieve a 10% reduction in power consumption compared to conventional installations. This enhancement significantly improves long-term operational stability and ensures higher carbon capture rates, greater end-product purity, and lower energy use in capture processes, reduced decarbonization costs, and decreased operational labor requirements. Currently, this technology has been successfully applied across industries such as power generation, chemical production, and resource extraction, delivering notable economic and environmental benefits.

In 2023, the 500 KTPA CCUS demonstration project undertaken by ShaanGu for China Energy Investment Corporation was successfully commissioned. The project achieves a CO₂ capture rate of over 90%, with an annual carbon reduction equivalent to planting 4.5 million trees or taking nearly 300,000 economy cars off the road.

In 2025, ShaanGu successfully secured the contract for the core compressor system to be used in the carbon capture facility of an integrated new energy + coal power generation and carbon capture project under CNPC. Upon operation, the project is expected to save 43,800 tons of standard coal annually, equivalent to reducing carbon emissions by 107,600 tons per year.